|

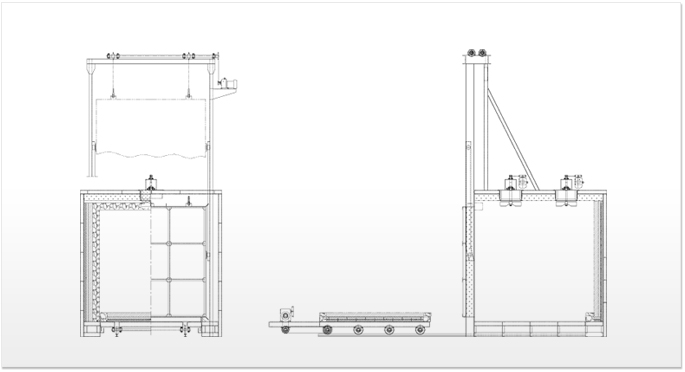

This furnace is provided to heat treat large structure or long parts such as section steel travelling certain distance to make in and output the part convenient.

Also powerful R/C fan is provided to help the heat be treated evenly to increase the temperature rapidly and control it precisely.

The furnace and rolling platform are heat insulated by fireproof bricks and ceramic resisting against the weight of parts. Cost saving is made available by improved heat efficiency.

|

|

|

|

Standards |

|

|

|

Model NO. |

Using temperature(°C) |

Fuel consumption(Kcal/hr)

|

Electric consumption (Kw/hr)

|

|

|

|

High Temperature |

Low Temperature |

High Temperature |

Low Temperature |

High Temperature |

Low Temperature |

|

1100 |

650 |

190,000 |

140,000 |

220 |

160 |

|

5 |

6 |

|

1100 |

650 |

370,000 |

275,000 |

430 |

320 |

|

10 |

6 |

|

1100 |

650 |

740,000 |

560,000 |

860 |

650 |

|

20 |

6 |

|

1100 |

650 |

1,100,000 |

825,000 |

1,280 |

960 |

|

30 |

6 |

|

1100 |

650 |

1,650,000 |

1,250,000 |

1,900 |

1,450 |

|

60 |

8 |

|

|

|

|

|

|

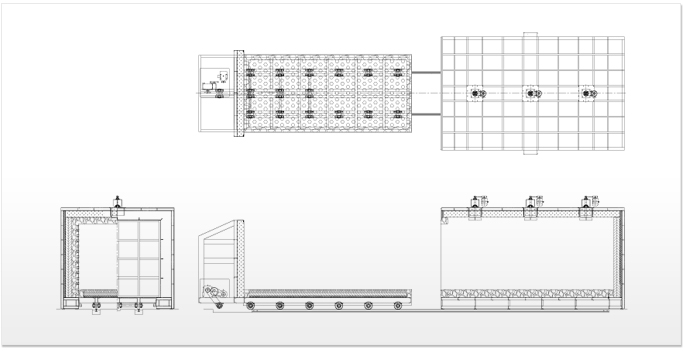

| 1. Features |

This type of furnace is mostly used to treat big quantity of products and easy for in and output. Excellent heat treatment is available by keeping the temperature distribution uniformed.

|

|

| 2. Specification |

- heat source: electricity, oil, gas.

- Temperature control: PID. On/Off, Proportion, Air/Oil Ratio ControlL

- Temperature : 1200℃

- Atmospheric gas: can be used |

|

| 3. Application |

- ANNEALING

- TEMPERING

- NORMALIZING

- HOMOGENIZING |

|

|

|

|

|

|

|

|

| |

|