|

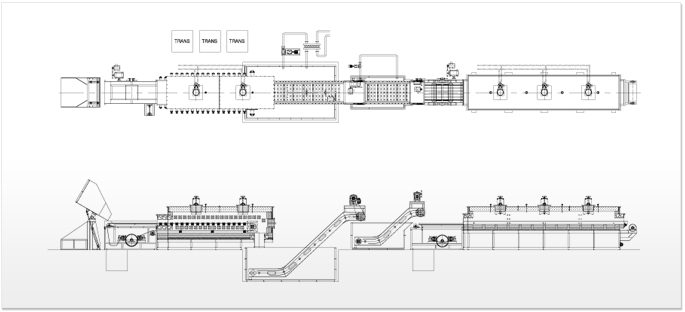

This furnace consists of Lift, Quenching, Oil tank, Conveyor, Washer Tank and tempering. It can treat small quantity in various types continuously. It can deal with decarburization and homogenizing simultaneously and can be manufactured in accordance with the size of products.

CH3OH, RX-GAS or DX-GAS are used as atmospheric gas in the furnace and stable atmosphere can be provided. As it is an automatic process, less manpower is needed and heat loss can be resisted to maximum to bring excellent energy saving. |

|

|

|

Q/T Standard |

|

|

|

Model NO. |

Using temperature(MAX) |

Fuel consumption(Kcal/hr) |

| |

Capacity (Kg/Hr) |

|

|

Quenching furnace (Kw/hr) |

|

|

|

|

1000 |

650 |

200 |

160 |

|

|

14,000 |

500 |

|

1000 |

650 |

400 |

240 |

|

|

20,000 |

1,000 |

|

1000 |

650 |

600 |

360 |

|

|

24,000 |

1,500 |

|

|

|

|

|

|

The standard carburizing |

|

|

|

Model NO. |

Using temperature(MAX) |

Fuel consumption(Kcal/hr) |

| |

Capacity (Kg/Hr) |

|

|

Quenching furnace (Kw/hr) |

|

|

|

|

1000 |

650 |

240 |

180 |

|

|

14,000 |

500 |

|

1000 |

650 |

440 |

280 |

|

|

20,000 |

1,000 |

|

1000 |

650 |

730 |

400 |

|

|

24,000 |

1,500 |

|

|

|

|

|

| 1. Features

|

It is generally used for mass production and less manpower is required due to simple automatic operation.

CH3OH, RX-GAS and DX-GAS are used as atmospheric gas and non oxidation heat treatment is available.

|

|

| 2. Specification |

- Heat source: electricity, Oil, Gas

- Temperature control: PID, On/Off, Proportion, Air/Oil Ratio Control

- Temperature : 1,000℃

- Atmospheric gas: can be used |

|

| 3. Application |

- QUENCHING

- TEMPERING

- CARBURIZINR

- Non oxidation treatment by using atmospheric gas |

|

|

|

|

|

| |

|